Gegevens_top

- +32(0)2-266 13 13

- LDA@LDA.be

Millibar

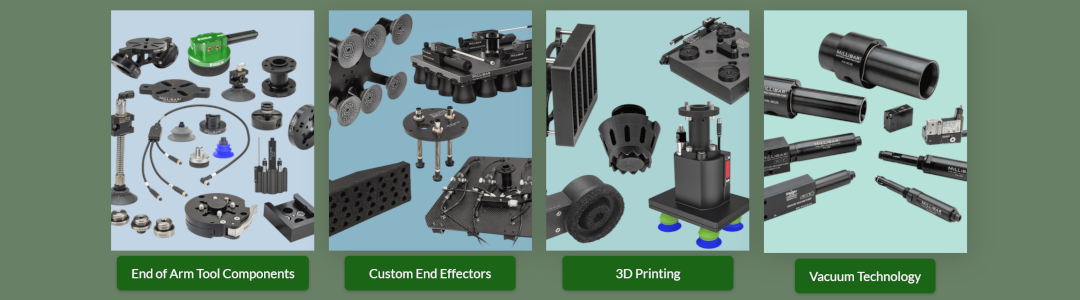

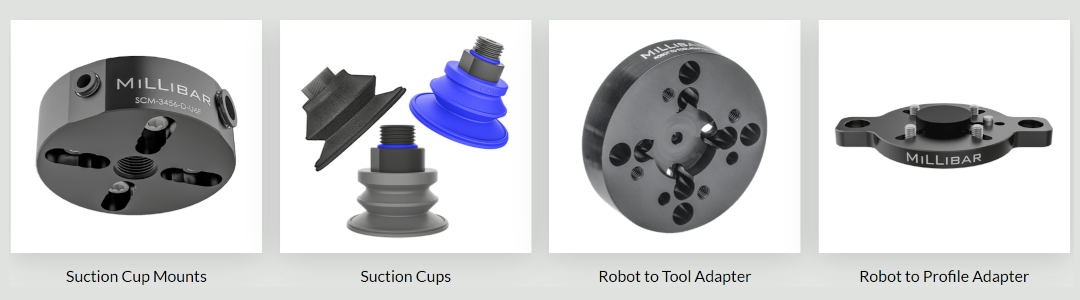

Millibar is your one-stop solution provider for robotic material handling and packaging.

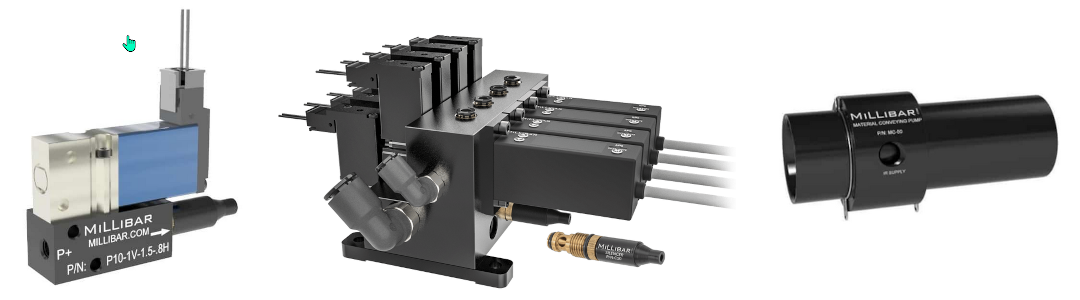

Millibar brings a generation of practical experience applying vacuum technology, and serves up the “best of the best” solutions for factory automation, robotics, material handling, packaging and many more applications. Our structure taps over 30 years of practical experience at every level of vacuum design, engineering and manufacturing.

Vacuum Design Engineering

Whether your vacuum application is widely implemented in industry or if it’s unique to your business operations, you deserve the best design solution available. At Millibar, our commitment to intelligent vacuum solutions ensures that we bring an innovative approach to designing optimal vacuum systems. When you put Millibar to work you apply our years of experience in vacuum system design and product development to a wide range of automation and process control applications. Our vacuum technology design services are perfect if you are faced with any of the following challenges:

• Lifting and moving a unique or unusually shaped item

• Grabbing an item in a unique location point

• Retrofitting an existing vacuum application

• Reengineering an existing system for improved performance

• Switching from electric to pneumatic

• Increasing the speed of processing, cycle time

• Lowering or eliminating maintenance costs

• Improving machine throughput

• Lowering failure rate

• Improving safety

Custom End of Arm Tooling

Millibar engineers have the proven field experience to solve your most challenging material handling requirements. Our custom robotic end of arm tooling solutions have run the gamut from handling bagged liquids, blister packaged hypodermic needles, removing flash from molded parts, to gripping complex shapes with irregular surfaces. This extensive knowledge base allows us to ask the right questions and avoid common pitfalls to create a solution that will work efficiently and effectively in your real-world application.

With our in-house Carbon Fiber 3D printing, lasers and multi-axis production equipment, we can mock-up a testable solution in a day, if not hours, depending on complexity. Our solutions are designed to minimize components to save assembly cost and provide trouble-free operation. We are so confident in our solutions, we provide a 100% guarantee that our solutions will work or your money back!

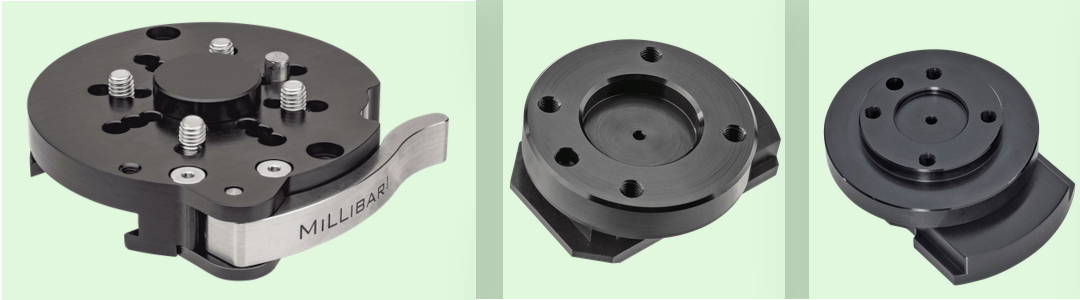

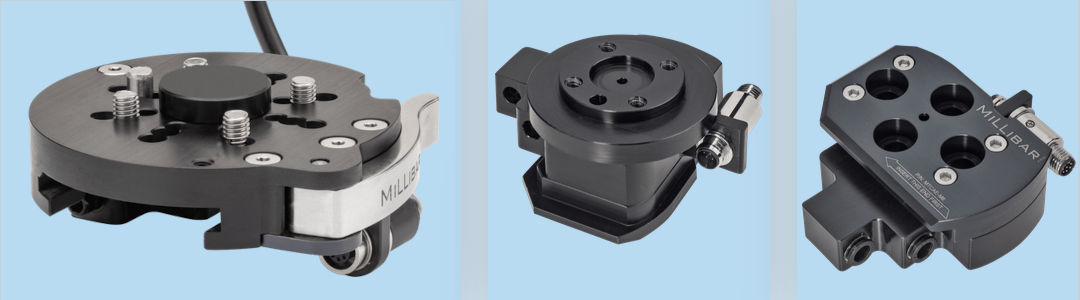

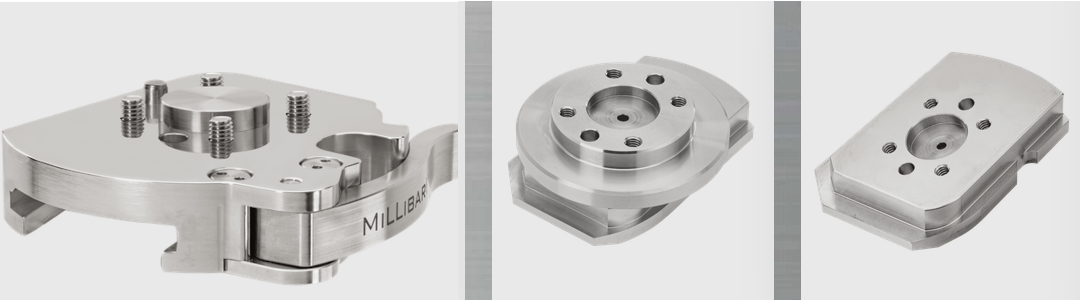

Millibar Manual Tool Changer Ecosystem

With the growing use of collaborative robots in production lines, Millibar has address the need for non-expert robot users to quickly switch between end of arm tooling components with the Millibar manual tool changer ecosystem. Our utility series manual tool changers can support applications requiring electric and air/vacuum. Our low profile series manual tool changers are for space limited applications that do not require utilities.

Millibar’s Manual Tool changer is a two-part solution:

Robot side - attaches to your robot’s wrist without the need of adapter plates.

Tool side - allows your Millibar pre-engineered or custom end of arm tooling solutions to quickly and easily slide-in and lock into place.

Our quick change solution is ideal for high-mix, low-volume applications. Even if your facility has a variety of robot brands, the Millibar Manual Tool Changer ecosystem allows tools to be shared between robots.