What is spray dampening?

Spray dampening is a common technology used in newspaper printing presses to apply ink release solutions to the non-printing surface of ink rollers. The precise dosing of the solution controls the dot gain and a high resolution. This technic allows to moisten the paper accurately and to reduce the waste of the waste water coming from the spray dampening system. As such, the amount of water is precisely managed and the amount of waste in the printing industry is reduced.

|

|

What’s the role?

The spray dampening system transfers a fine and uniform wet film to the printing plate. This also serves to avoid the return of particles coming from the printing plate or ink rollers.

Spray dampening must complete the following tasks:

- Wetting of the no-printing areas of the plate quickly, uniformly and without excess.

- Creating a good emulsion in the ink.

- Maintaining the hydrophilic type of the plate while protecting it against wear (by lubrication) and oxidation (by adsorption of a protective film).

- To evaporate as much as possible before being transferred to the paper.

- Cooling the ink film.

- To evacuate all particles that appear on the plate or the blanket.

To protect the rolls against wear because of abrasion

The different advantages of spray dampening:

- More precision

- Different formats are available

- Reduce the consummation of additives, water, alcohol and filters

- Easy installation

- Not expensive

- Return on investment can be fast

This no-contact system projects the spray from the bubbler to the other dampening rollers. This projection can be done in 3 ways:

- With a brush in the tank which rubs against a blade

- With a rotating system that uses the centrifugal force

- With nozzles that spray drops under pressure

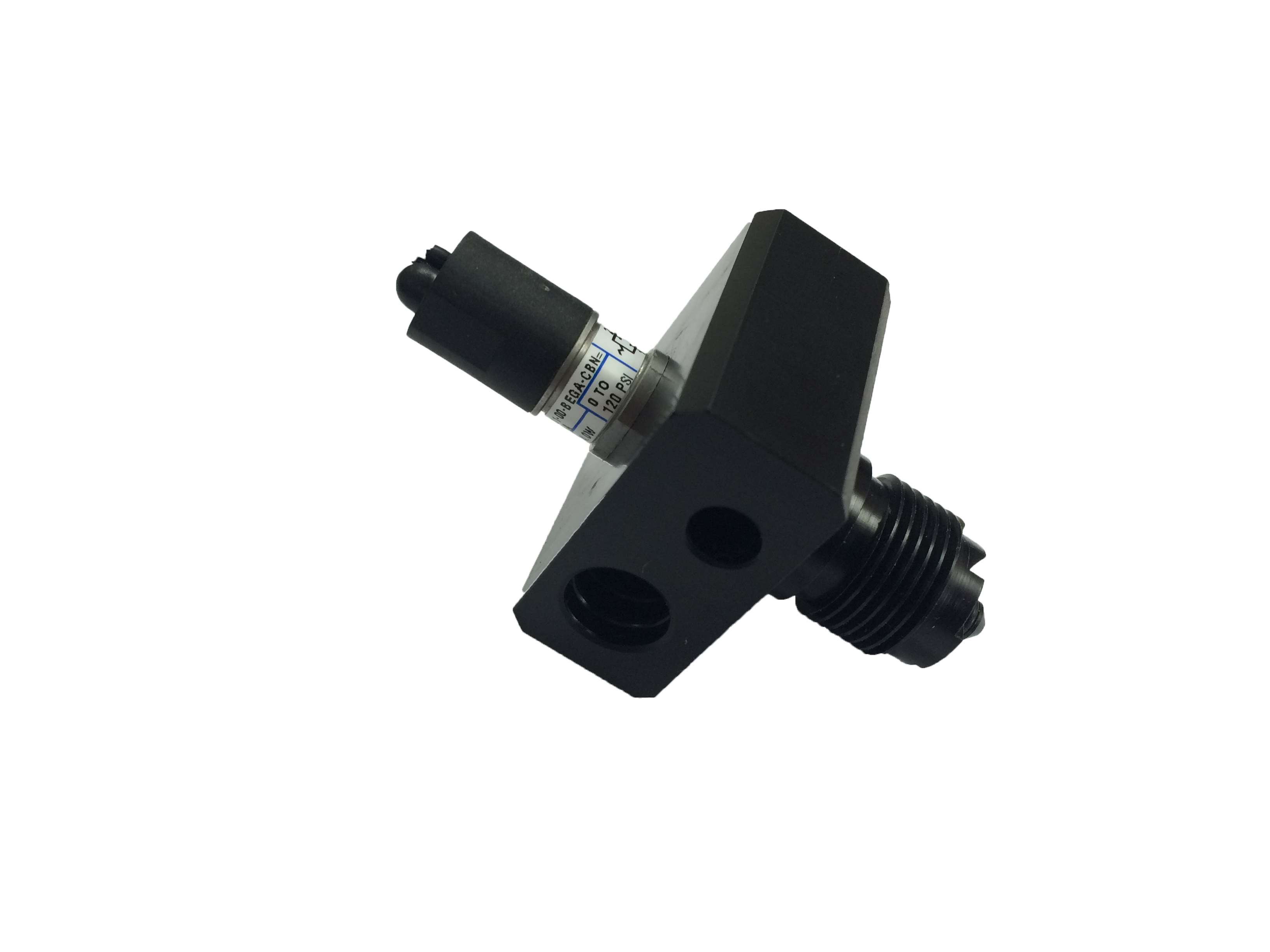

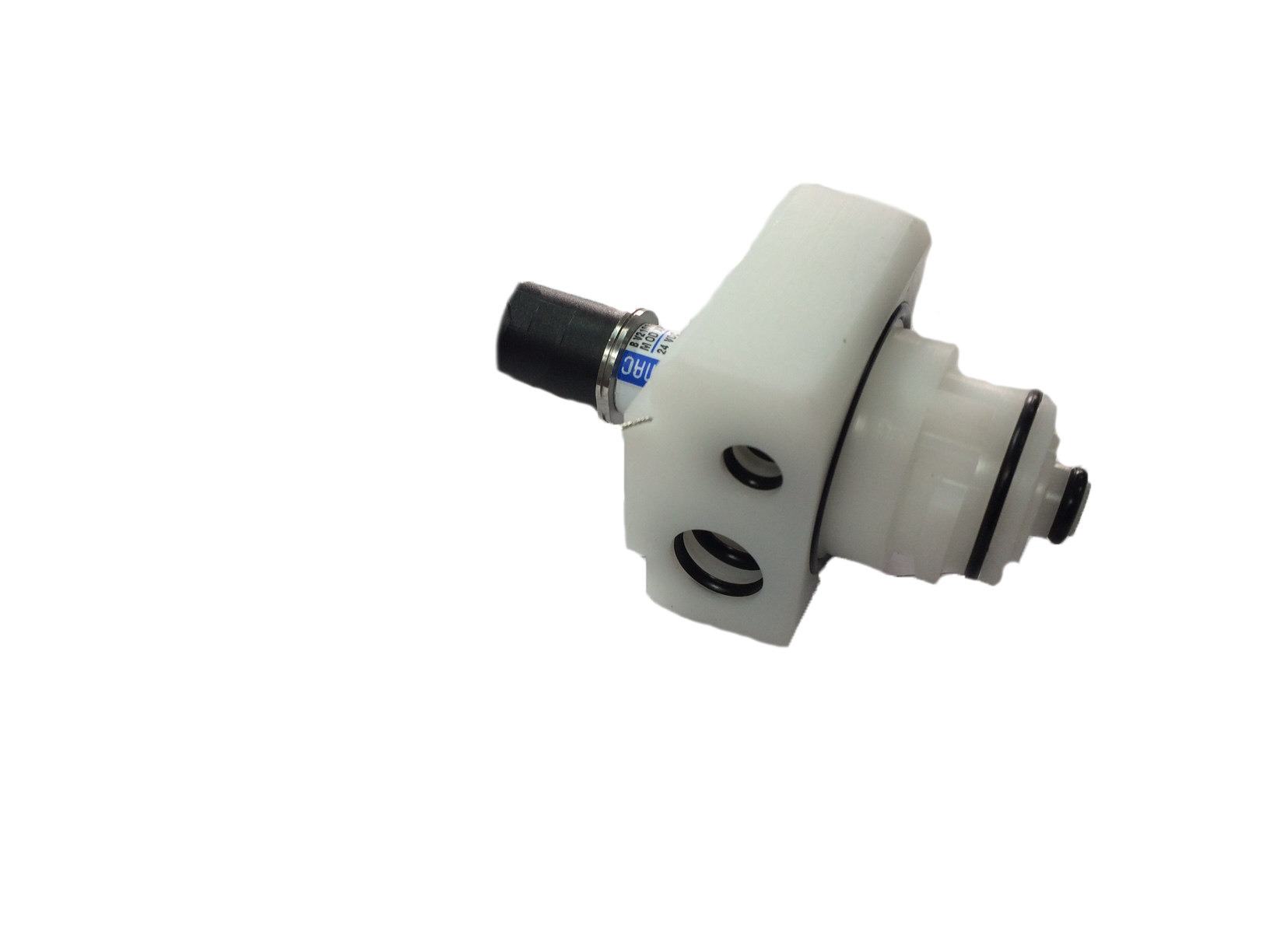

LDA has a replacement system for Baldwin or Technotrans valves. This system allows you to save money while increasing production and reducing the labour cost. It also allows you to use less replacement parts.

|

Customer requirements |

Customer benefits |

|

Easy maintenance |

Drop-in replacement compatible with existing spray dampening system |

|

Reduce set up time and associated costs |

Replacement of water and the air/water systems |

|

Similar flow from valve to valve ensuring consistent spray volumes |

Easy valve replacement -> no manifold removal needed |

|

Longer life |

Balanced design |

|

Liquid Bullet valve with D-Flex technology tested over billions of cycles |

|

|

Consistent and repeatable response times over the lifetime of the valve. |

Download the document via this link

Download the document via this link

![]()

Have a question for our specialists? Call +32 (0)2-266 13 13

www.LDA.be - This email address is being protected from spambots. You need JavaScript enabled to view it.

![]()

Hoge Buizen 53

1980 Eppegem

Belgium